Using our extensive cut capacities (plasma, laser, water jet and sawing), we can guarantee our clients high quality products with tight tolerances and delivered in a fast and reliable time frame delivery.

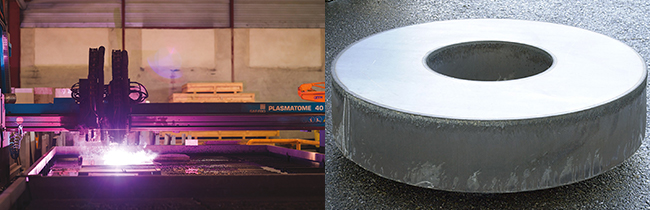

The most economical solution for all forms of stainless steel and nickel alloys pieces.

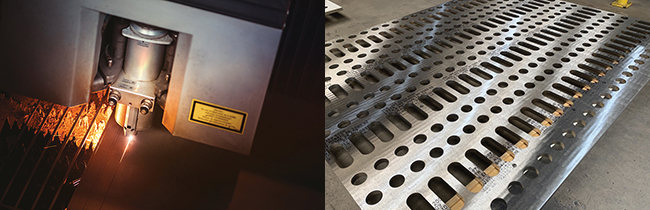

The high precision of the laser allows tight tolerances up to 50mm thickness. Also ideal for large series of pieces.

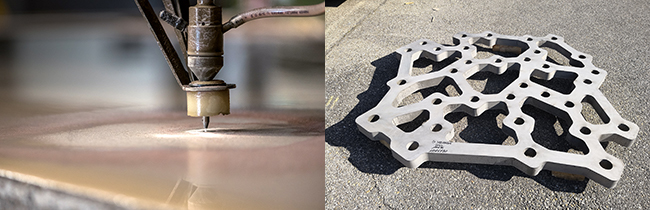

High-pressure water jet cutting reduces or avoid a possible machining. No shape or thickness limitations, cold cutting without heat affected zone (HAZ). Ideal for complex cutting of stainless steels and nickel alloys.

Sawing gives a beautiful straight cut as a result of the cold process. Is particularly suitable for thick strips, blocks and plates up to a maximum of 150 mm thick.

Compare tolerances according their cutting processes

| THICKNESS (mm) |

SAW | |||||

|---|---|---|---|---|---|---|

| L ≤ 3 000 mm | 3 001 < L ≤ 6 000 mm | L > 6 000 mm | ||||

| W ≤ 1 000 mm | W > 1 000 mm | W ≤ 1 000 mm | W > 1 000 mm | W ≤ 1 000 mm | W > 1 000 mm | |

| 1 … 150 | L : 0 / + 3 mm W : 0 / + 2 mm |

L : 0 / + 3 mm W : 0 / + 4 mm |

L : 0 / + 5 mm W : 0 / + 2 mm |

L : 0 / + 5 mm W : 0 / + 4 mm |

L : 0 / + 8 mm W : 0 / + 3 mm |

L : 0 / + 8 mm W : 0 / + 4 mm |

| Comment | – | |||||

| THK (mm) |

LASER | ||

|---|---|---|---|

| L ≤ 300 mm | 301 < L ≤ 1000 mm | L > 1000 mm | |

| 1 | ± 0.3 mm | ± 0.5 mm | ± 0.6 mm |

| 5 | |||

| 10 | |||

| 15 | ± 0.5 mm | ± 0.8 mm | ± 1 mm |

| 20 | |||

| 25 | ± 1 mm | ± 1.25 mm | ± 1.5 mm |

| 30 | |||

| 35 | To be defined with new lasers 15 et 20 KW | ||

| 40 | |||

| 50 | Not Applicable | ||

| 60 | |||

| 70 | |||

| 80 | |||

| 90 | |||

| 100 | |||

| 110 | |||

| 120 | |||

| 130 | |||

| 140 | |||

| 150 | |||

| Comment | – | ||

| THK (mm) |

WATER JET | |||||

|---|---|---|---|---|---|---|

| L ≤ 1000 mm | 1001 < L ≤ 3000 mm | 3001 < L ≤ 6000 mm | L > 6000 mm | |||

| Basic | Normal | Fine | B, N or F | B, N or F | B, N or F | |

| 1 | ± 0.8 mm | ± 0.6 mm | ± 0.4 mm | ± 2 mm | ± 3 mm | ± 4 mm |

| 5 | ||||||

| 10 | ± 1 mm | ± 0.7 mm | ± 0.4 mm | ± 2 mm | ± 3 mm | ± 4 mm |

| 15 | ||||||

| 20 | ± 1.5 mm | ± 1 mm | ± 0.5 mm | ± 2 mm | ± 3 mm | ± 4 mm |

| 25 | ||||||

| 30 | ||||||

| 35 | ||||||

| 40 | ||||||

| 50 | ± 2 mm | ± 1.5 mm | ± 1 mm | ± 2 mm | ± 3 mm | ± 4 mm |

| 60 | ||||||

| 70 | ||||||

| 80 | ||||||

| 90 | According to plan or specification | |||||

| 100 | ||||||

| 110 | ||||||

| 120 | ||||||

| 130 | ||||||

| 140 | ||||||

| 150 | ||||||

| Comment | B : Basic, N : Nomal, F : Fine Cutting angle included in tolerance = 0.2 mm per 10 mm thickness |

|||||

| THK (mm) |

PLASMA | ||

|---|---|---|---|

| L ≤ 2000 mm | 2001 < L ≤ 6000 mm | L > 6000 mm | |

| 1 | Ext. cut 0 / + 3 mm Int. cut -3 / 0 mm |

Ext. cut 0 / + 5 mm Int. cut -5 / 0 mm |

Ext. cut 0 / + 8 mm Int. cut -8 / 0 mm |

| 5 | |||

| 10 | |||

| 15 | |||

| 20 | |||

| 25 | |||

| 30 | |||

| 35 | |||

| 40 | |||

| 50 | |||

| 60 | |||

| 70 | Ext. cut 0 / + 5 mm Int. cut -5 / 0 mm |

Ext. cut 0 / + 8 mm Int. cut -8 / 0 mm |

Ext. cut 0 / + 10 mm Int. cut -10 / 0 mm |

| 80 | |||

| 90 | |||

| 100 | |||

| 110 | |||

| 120 | |||

| 130 | Ext. cut 0 / + 8 mm Int. cut -8 / 0 mm |

Ext. cut 0 / + 10 mm Int. cut -10 / 0 mm |

Ext. cut 0 / + 12 mm Int. cut -12 / 0 mm |

| 140 | |||

| 150 | |||

| Comment | Indicative taper of 1 – 3 mm/ face for thickness < 60 mm Indicative taper of 3 – 6 mm/ face for thickness > 60 & < 120 mm Indicative taper of 3 – 10 mm/ face for thickness >120 mm |

||

| THK (mm) |

PLASMA HD | ||

|---|---|---|---|

| L ≤ 2000 mm | 2001 < L ≤ 6000 mm | L > 6000 mm | |

| 1 | Ext. cut 0 / + 1 mm Int. cut -1 / 0 mm |

Ext. cut 0 / + 3 mm Int. cut -3 / 0 mm |

Ext. cut 0 / + 4 mm Int. cut -4 / 0 mm |

| 5 | |||

| 10 | |||

| 15 | Ext. cut 0 / + 2 mm Int. cut -2 / 0 mm |

Ext. cut 0 / + 4 mm Int. cut -4 / 0 mm |

Ext. cut 0 / + 5 mm Int. cut -5 / 0 mm |

| 20 | |||

| 25 | Ext. cut 0 / + 3 mm Int. cut -3 / 0 mm |

Ext. cut 0 / + 4 mm Int. cut -4 / 0 mm |

Ext. cut 0 / + 6 mm Int. cut -6 / 0 mm |

| 30 | |||

| 35 | Not Applicable | ||

| 40 | |||

| 50 | |||

| 60 | |||

| 70 | |||

| 80 | |||

| 90 | |||

| 100 | |||

| 110 | |||

| 120 | |||

| 130 | |||

| 140 | |||

| 150 | |||

| Comment | Indicative taper of 0.5 – 1 mm/ face for thickness ≤ 20 mm Indicative taper of 0.5 – 1.5 mm/ face for thickness > 20 & ≤ 30 mm |

||